Chiudi

Glaciale – architettura del semifreddo

€ 42,99 - € 80,00Fascia di prezzo: da € 42,99 a € 80,00Pasticceria Evolutiva – Logica, Didattica e Contemporaneità

€ 49,99 - € 90,00Fascia di prezzo: da € 49,99 a € 90,00CLASSICO FUTURO – La pasticceria semplice, leggera e pratica

€ 44,99 - € 85,00Fascia di prezzo: da € 44,99 a € 85,00Il volo di un Piaf – Decor 2000

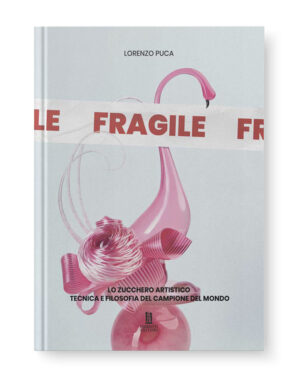

€ 29,99 - € 55,00Fascia di prezzo: da € 29,99 a € 55,00Fragile – Artistic sugar technique and philosophy of the world champion

€ 88,99 - € 120,00Fascia di prezzo: da € 88,99 a € 120,00TuttoGelato

€ 20,00 - € 40,00Fascia di prezzo: da € 20,00 a € 40,00Pasticceria Internazionale

€ 4,99 - € 135,00Fascia di prezzo: da € 4,99 a € 135,00The GELATO you are looking for

€ 22,99 - € 50,00Fascia di prezzo: da € 22,99 a € 50,00Il Mais in Italia – Storia Naturale e Agricola

€ 19,90 - € 50,00Fascia di prezzo: da € 19,90 a € 50,00Il cibo l’uomo e la cultura

€ 19,90 - € 50,00Fascia di prezzo: da € 19,90 a € 50,00MATER FERMENTUM – La genesi della pasta fermentata

€ 52,99 - € 90,00Fascia di prezzo: da € 52,99 a € 90,00Fragile – Lo zucchero artistico, tecniche e filosofia del campione del mondo

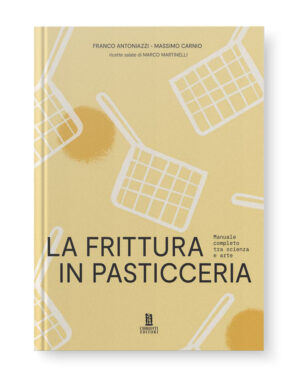

€ 89,99 - € 120,00Fascia di prezzo: da € 89,99 a € 120,00La frittura in pasticceria – manuale completo tra scienza e arte

€ 28,99 - € 50,00Fascia di prezzo: da € 28,99 a € 50,00Nuovo abbonamento Alimenti Funzionali + Gift Card 10€ in regalo!

€ 20,00 - € 40,00Fascia di prezzo: da € 20,00 a € 40,00Nuovo abbonamento Industrie Alimentari + Gift Card 10€ in regalo!

€ 70,00 - € 150,00Fascia di prezzo: da € 70,00 a € 150,00Nuovo abbonamento Ingredienti Alimentari + Gift Card 10€ in regalo!

€ 50,00 - € 105,00Fascia di prezzo: da € 50,00 a € 105,00Nuovo abbonamento Tecnica Molitoria + Gift Card 10€ in regalo!

€ 55,00 - € 125,00Fascia di prezzo: da € 55,00 a € 125,00Nuovo abbonamento TuttoGelato + Gift Card 10€ in regalo!

€ 20,00 - € 40,00Fascia di prezzo: da € 20,00 a € 40,00Nuovo abbonamento Industrie delle Bevande world wide bottling + Gift Card 10€ in regalo!

€ 45,00 - € 100,00Fascia di prezzo: da € 45,00 a € 100,00